Automotive Algorithms: Buffing Combustion

May 20, 2019

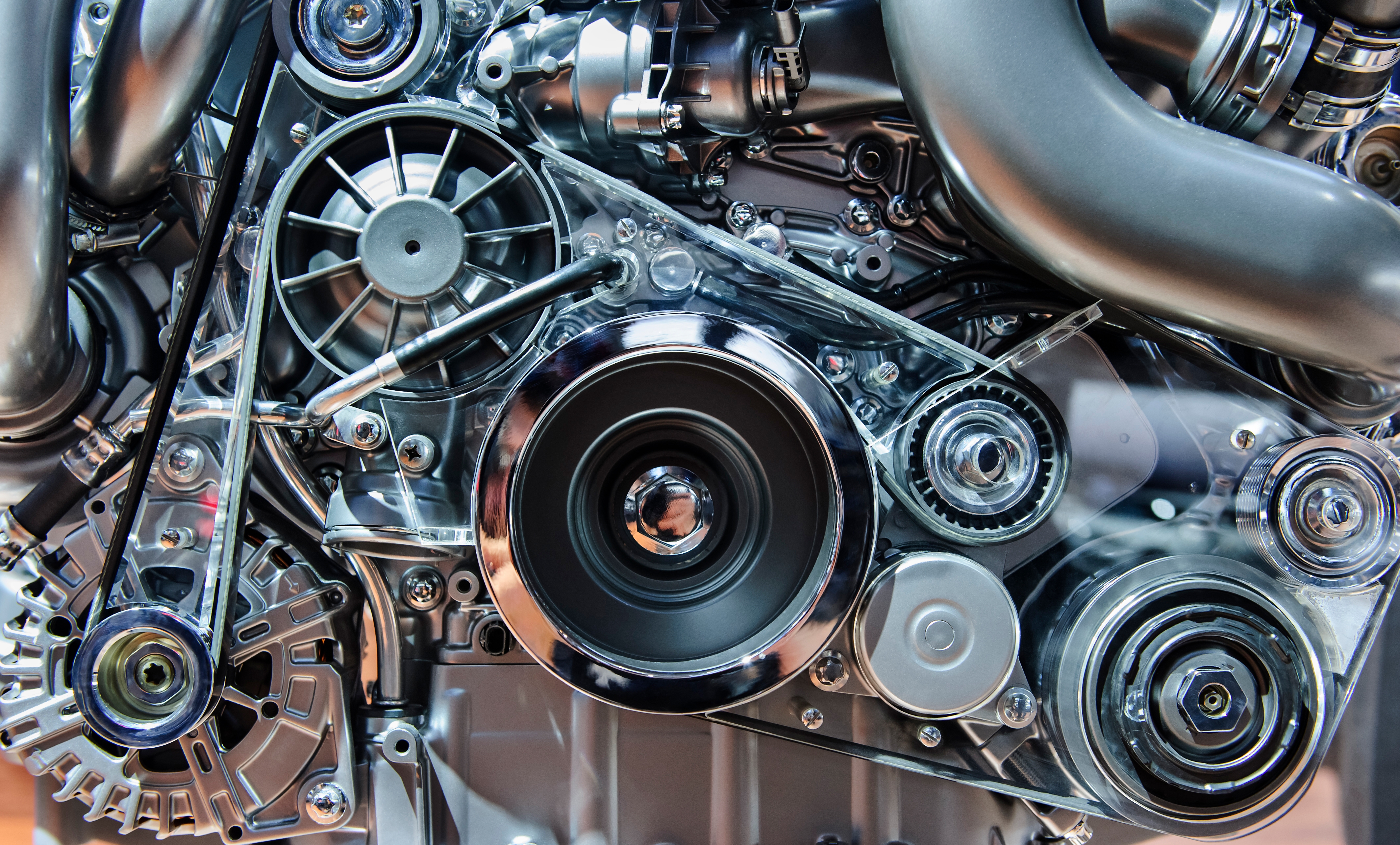

The days of the internal combustion engine (ICE) may be numbered, but that number is still large. Internal combustion engines are the primary mode of power for today’s vehicles, and the International Council on Clean Transportation projects that 3 billion more ICE vehicles will be sold before 2050.

“For vehicles powered by internal combustion, efficiency is critical,” said Haibo Zeng, ECE assistant professor. “There is a lack of focus on ICEs, and a lot of room to improve,” he said.

The improvement of internal combustion engine operation can have profound and immediate impact, according to Zeng. “Our work can improve both operational efficacy and vehicle safety, and the lessons we learn apply not only to ICEs, but also to electric and hybrid electric vehicles, and to the transportation sector as a whole.”

Optimizing

When an engineer adjusts any parameter—routing, path planning, speed planning, or power train—it affects the engine map, which is a characterization of an engine’s efficiency. To optimize the system, researchers should holistically consider all layers in the vehicle, not just individual components, said Zeng.

But if all the layers are considered in a holistic way, some critical design aspects, like timing requirements, become more difficult to optimize, Zeng said.

In the past, design engineers spent hours or days fine-tuning parameters, said Zeng. But now, the goal is to optimize on the fly, so the runtime of parameter optimization algorithms needs to match the dynamics of the vehicle, which is milliseconds to seconds.

Zeng and his team are developing algorithms to meet those requirements, and results are promising: “We have already shown that this type of speed is possible in a few cases,” said Zeng.

Monitoring and enforcing safety

Zeng is also applying formal methods to improve functional safety and remove system design defects and implementation bugs, which can be caused by human error or from uncertainties in the environment.

But even in the absence of design defects, an ICE system is still vulnerable to cyberattack, said Zeng. “Today’s cars rely heavily on connectivity, which is meant to increase comfort and safety, but it also opens the door to attackers.”

To improve security, Zeng and his team are developing an advanced safety enforcement mechanism “safety guard” that can enforce system safety and make corrections in real time.

By building and housing the safety guard separately from the internal system, Zeng and his team will be able to protect the guard from malicious attack, keep it cost-effective, and allow it to oversee normal ICE operation without interfering with the system’s normal function.