Building electric road warriors

As of October 2018, there were more than 1 million electric vehicles on American roads, according to the Edison Foundation. The latest models can travel between 150 and 300 miles per charge with a standard-issue battery. The problem, says ECE’s Qiang Li, is the time it takes to recharge.

“The most popular charger right now is the overnight garage model,” said Li who is an associate professor working in the Center for Power Electronics Systems. “Many companies are trying to develop high-power battery chargers, which would recharge a drained battery in an hour—but an hour is still too long.”

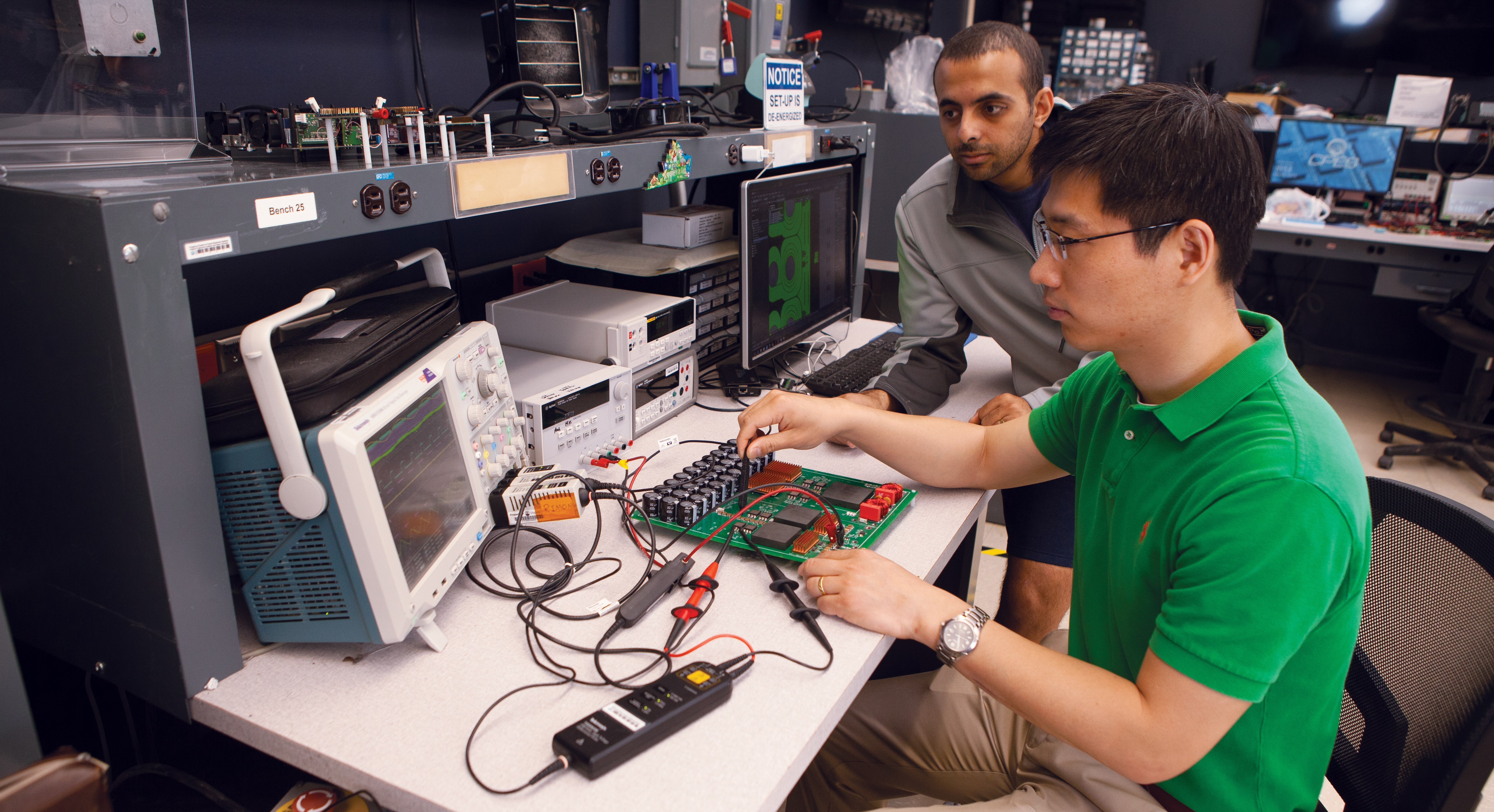

Li and his colleague Fred Lee (University Distinguished Professor emeritus) together with their students have been developing techniques to cut charging times down to 10 to 30 minutes and increase the efficiency of both the chargers and the charging stations.

The key, said Li, is increasing the power and shrinking the charger size—both inside and outside the car.

To reduce charger size, Li is incorporating emerging semiconductor materials, including gallium nitride and silicon carbide, to increase switching frequency and reduce converter loss using soft-switching techniques.

Transformers and inductors are bulky elements inside a converter, and they are some of the more labor-intensive components to fabricate. Li developed a way to use a standard printed circuit board (PCB) to build both transformer and inductor and reduce their size significantly.

“Usually a PCB is only used as substrate, and the discrete transformer and inductor go on top,” said Li. “I’m trying to build an integrated transformer and inductor in a PCB.”

This reduces size and simplifies manufacturing.

“After we apply all this technology, we will eventually be able to decrease the size of a charger by half or even three quarters,” said Li. “And we’ll be able to make efficiency even higher.”

Li and his team have already developed prototypes of the 7 kW on-board chargers and 25 kW off-board chargers. Besides working with industry partners to transfer this technology for commercialization, they are also working on a solid-state-transformer-based 400kW ultra-fast off-board charger.